UMC 2020: By the Numbers

This year has challenged many companies to prioritize growth and innovation in the face of unprecedented uncertainty. But through 50 years of manufacturing, we’ve learned sitting back or playing it safe are not sustainable strategies for long-term success. During volatile times like those we’ve experienced in 2020, UMC’s experience and diversification brings a level of stability that other contract manufacturers can’t deliver.

Saying Yes to The Right Opportunities

Balancing new opportunities while minimizing risk is a difficult but necessary part of what we do as a leading contract manufacturer. We know a good opportunity when we see one. A project that requires tight tolerances, exacting standards, and precision manufacturing excellence is a good fit. On every new part, whether it’s new to the market or just new to our manufacturing floor, we use our expertise to bring value and establish trust.

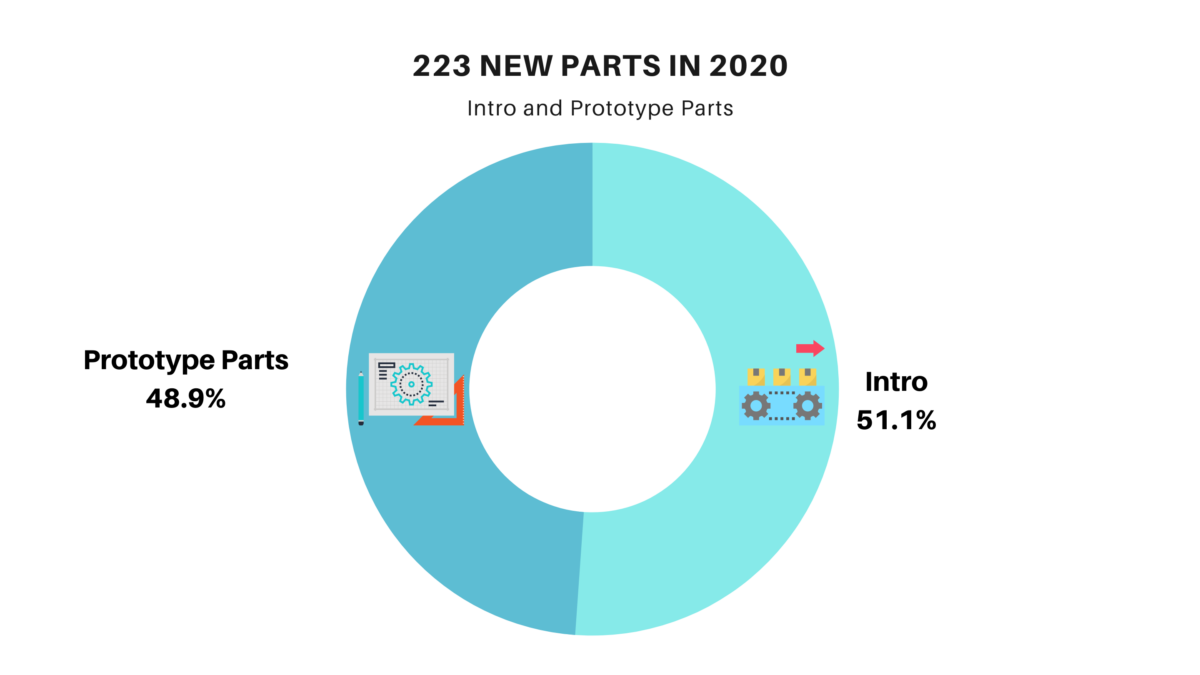

223 New Parts

This year, UMC ran 223 new parts. We classify a new part as one that we have not run before on our manufacturing floor. We break those new part projects into two categories: intro jobs and prototype jobs.

114 Intro Parts

Intro jobs are parts that are in production but being run at UMC for the first time. With every intro job, we come alongside the manufacturer to discover and explore opportunities for enhancing design and manufacturing for a more reliable end product.

109 Prototype Jobs

Prototype jobs are parts that are still in the product development phase. UMC collaborates with product development teams in the early stages and throughout the launch process to improve manufacturability by providing ideas, approaches, and designs that enhance quality and reliability while reducing costs.

Saying yes to innovative projects from successful manufacturers keeps us abreast of the advancements and developments in the industries we support. Every new part gives our team experience that we use to add value to developing and optimizing future parts.

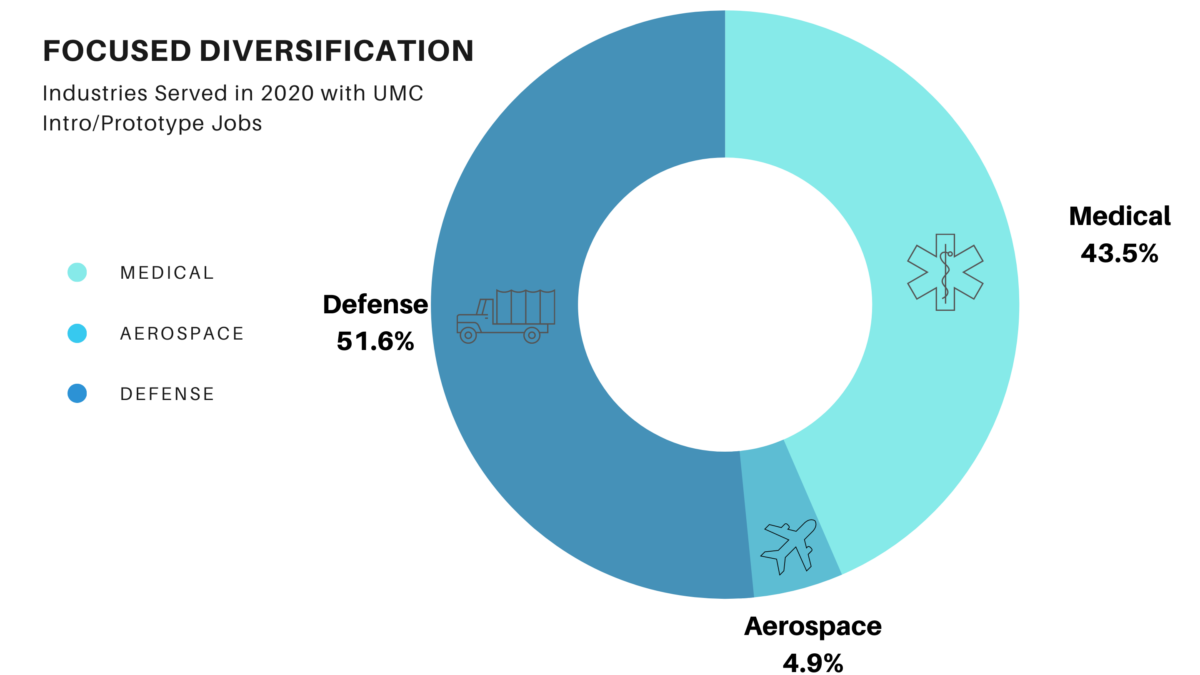

Applying Focused Diversification

Smart diversification means that even as we expand, we stay true to and build on our core strengths. Of the 223 intro and prototype jobs we saw in 2020, 97 were medical parts, 11 were aerospace parts, and 115 were for defense companies. Our involvement in these demanding, highly-regulated, fast-paced industries consistently exposes us to the latest developments—which we then bring to the table as we tackle new customer challenges and opportunities.

Our customers recognize the value our work in other industries brings to the table, especially when it comes to standards and certifications. Even our customers who do not require NADCAP certification appreciate the rigorous focus the certification process puts around quality, cost effectiveness, and continuous improvement.

Remaining Ready for Growth

The work we’ve done with our customers in 2020 reinforces the path we’ve chosen as a company dedicated to advancing precision manufacturing for the leading OEMs in the world. These numbers remind us that, especially as the world changes, innovation, advancement, and growth can propel us forward. With ongoing investments in technology and initiatives like the Armstrong Project, UMC will continue to reach for results that go beyond others.