Machines, Materials & Technology

With state-of-the-art machines, unique technologies, advanced materials, and a powerful supply chain, UMC’s shop is the perfect platform for our team of expert engineers and machinists to develop complex parts and products.

Our Machines

From swiss to mill to automation and more, we’re constantly reinvesting in the latest and greatest machine tool technology.

Multi-Tasking Department

Mill / Turn 9 Axis

- DMG Mori NTX1000 Gen2 (3)

- DMG Mori NT3150 (1)

- DMG Mori NT3200 (3)

- DMG Mori NTX1000 (2)

- DMG Mori NTX1000 w/Collaborative Robot (2)

Mill / Turn Triple Turret

- DMG Mori NZX1500 (2)

Milling Department

Mill / Horizontal 4 Axis

- Matsuura ES-450H (1)

Mill / Vertical 4 Axis

- Matsuura 800VG2 (2)

- Haas VF-3SS (1)

- Fanuc Robo Drill (1)

- Okuma MB-46VAE (2)

- DMG Mori NVX5080/40-Pr (1)

- DMG Mori NVX5080/40-Pr w/CR-15 Robot (1)

Mill / Vertical 3 + 2 Axis

- Haas VF-3SSYT (6)

- Matsuura 800VG2 (1)

Mill / Vertical 5 Axis

- Matsuura MX-330 PC10 (4)

- Matsuura MX-520 PC4 (2)

- Matsuura MX-520 (1)

- Matsuura MX-520 w/CR-15 Robot (1)

Turning Department

- DMG Mori SL-250B/500 (2)

- DMG Mori SL-250C/500 (1)

- DMG Mori SL-253B/500 (2)

- Mori Seiki NL-2000Y/500 (1)

- Nakamura SC-300 (1)

- Eguro Nuclet 10GL (1)

- Haas SL-20 Turn (2)

Swiss Department

- Citizen L20 (2)

- Citizen M20 (2)

- Star SR-202RIV Type B (2)

EDM Department

- Charmilles 440CC (3)

- Charmilles 240CC (3)

- Charmilles 200SP (1)

- EDM Tending Robots w/3R Pallet Pools (2)

Additional Services

- Laser Marking – FOBA M3000P (1)

- 3D Printing – Stratasys Fortus 450mc (1)

- 3D Printing – Stratasys F370 (1)

- Automated Part Washing System (2)

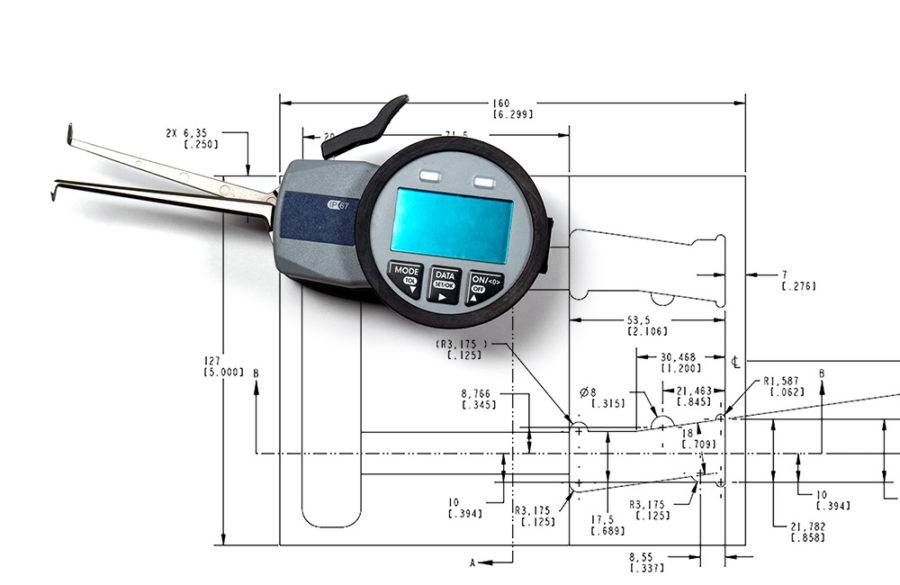

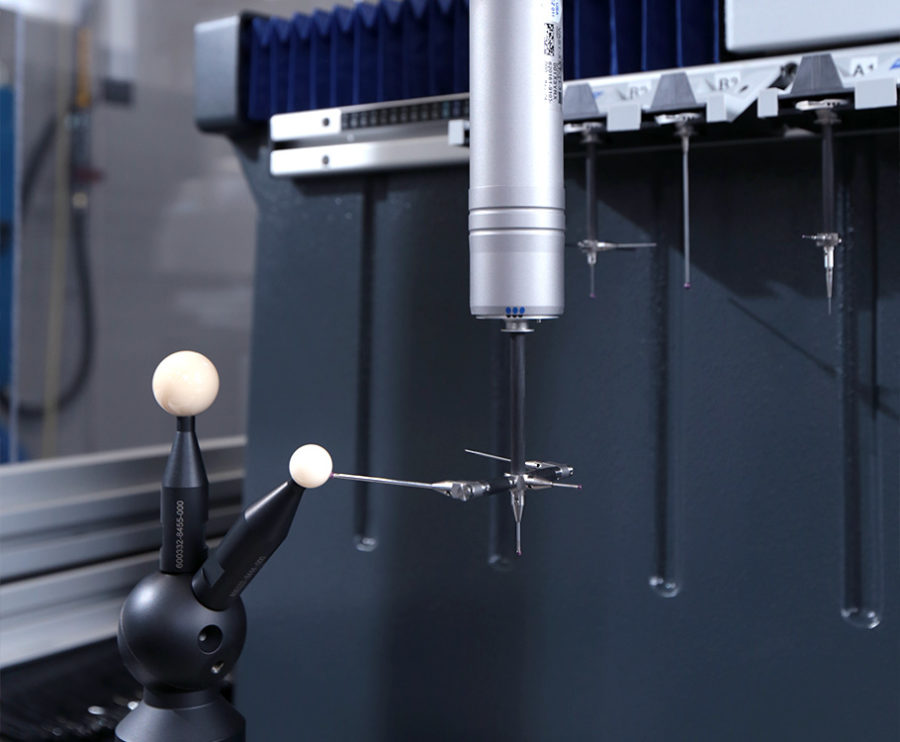

Automated Inspection

- Zeiss Duramax 555 CMM (2)

- Zeiss Contura G2 CMM (1)

- Zeiss Contura G2 CMM w/CR-15 Robot (1)

- Zeiss O-Inspect Multi Sensor CMM (1)

- Brown & Sharp Mistral 775 CMM (2)

- Brown & Sharp One 775 CMM (1)

- Brown & Sharp Global 575 CMM (12)

- Micro-Vu Vertex 251UC VCMM (3)

- Keyence Vision System VCMM (5)

UMC has developed unique technology to integrate our production and inspection equipment.

Our talented staff has undergone rigorous training to optimize this technology and deliver ultimate value for our customers through quality, speed to market, and cost savings.

UMC leverages industry leading technology in our facilities. Here is a sampling of the software and systems that we operate with: Epicor, Pro Engineer, MasterCAM, 1factory, QC Calc, Minitab, Vericut and WebDNC.

Materials

For five decades, we’ve mastered the use of these materials to deliver superior products.

High Temperature Alloys

- Inconel

- Hastelloy

- Waspaloy

- Stellite

Aluminum

- 2000 Series

- 6000 Series

- 7000 Series

- Others

Carbon Steel

- 1000 Series

- 1100 Series

- Others

Plastics

- PEEK

- Acetal

- Nylon

- Polyurethane

- Polyethylene

- Ultem

Titanium

- Ti-6Al-4V

- Ti-6Al-4V ELI

- Other Ti grades

Copper Alloys

- Bronze Brass

Stainless Steels

- 13-8Mo

- 15-5Ph

- 17-4Ph

- 300 Series

- 400 Series

- Nitronic

- A-286

Cobalt Alloys

- Elgiloy

- MP35N

You can rely on our integrated, timely, and scalable supply chain.

-

Partnerships

Our partnerships with global leaders rely on flexibility, ingenuity and speed. We manage a reliable and robust supply base to maximize supply chain efficiency and customer value. Planning and communication ensure our operations are optimized throughout the supply chain. We focus on creating alignment throughout our production as well as with our suppliers, giving them timely visibility to requirements and streamlined flow down to their operations.

-

Materials Management

The foundation of our supply chain is built on a core ERP system, thorough capacity planning, MRP, stringent business processes, and supplier validation. We enhance customer value by offering supplier managed inventory, customer inventory, and dock-to-stock shipping. We employ closed loop materials management, real-time tracking of production operations, and systems traceability.

-

Continuous Improvement

Our focus on continuous improvement and use of Lean Manufacturing and Six Sigma practices have allowed us to continue to streamline efficiencies across our supply chain. We strive to exceed customer expectations by continually strengthening our processes and systems. We carefully manage resources by maintaining optimal levels of capacity, labor, and inventory. You can rely on our integrated systems and processes to meet your needs.

-

Supply Base

We also manage a robust supply base and we partner with leading providers of anodization, laser welding, chrome plating, passivation, electropolishing, sinker EDM, gun drilling, grinding, heat treat, stamping, and electro-chemical etch. When partnering with UMC, you can trust that quality is at the top of our list.