We’re engineering a brighter future.

Our experienced engineering staff is focused on supporting you from early development throughout production. With services designed to match the unique needs of each client, UMC applies the highest standard of quality, efficiency and product delivery in order to ensure success and added value.

Our expert team is ready to solve your most complex challenges.

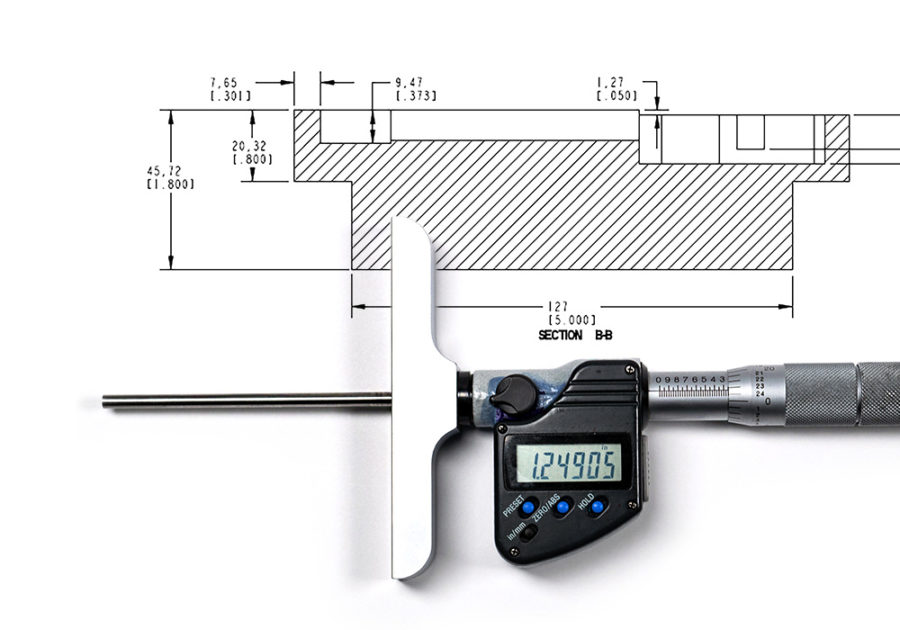

We are FDA 21 CFR Part 820 Compliant and have the highest level of engineering support at your side. By leveraging advanced methods, our machinists’ broad experience and know-how, and tools to predict process capability from the start—we ensure your goals are achieved without sacrificing functional integrity, speed or budgetary requirements. We will partner with your product development teams early on in the process – harnessing creativity and innovation to maximize efficiency and reduce overall costs in the program. Design for Manufacturability (DFM) is a valuable tool that we incorporate to ensure a successful product launch and mitigate risk for technical issues and delays.

Our collaborative approach is designed to address the challenge of your product’s demanding specifications and optimize speed to market and total cost of quality.

Experience

We are armed with experience when it comes to:

- Design for manufacturing (DFM)

- Design for assemblies (DFA)

- Design of experiments (DOE)

- Process characterizations (PC)

- Gage repeatability and reproducibility (Gage R&R)

- Process capability

- Pre-production Part Approval Process (PPAP)

- Failure Mode and Effect Analysis (FMEA)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

Employee Certifications

- Geometric dimensioning and tolerancing practices (GD&T)

- Advanced Statistical Process Control

Continuous Improvement

We maximize customer value by partnering our continuous improvement practitioners and engineering staff to drive efficiencies by applying Lean Manufacturing and Six Sigma techniques throughout our operations. We’re engineering a brighter future.

Software

The following software is used in our daily operations:

- MasterCAM

- Vericut

- Pro Engineer

- QC Calc

- 1factory

- Epicor ERP

- Minitab

- WebDNC

We achieve efficiency and consistency through prototyping and creativity.

Speed is life. UMC’s prototyping services utilize dedicated resources to enable completion of small quantities, as few as one, within days. This independent department supports our customers with their qualification and testing requirements and assists you in your effort to be first to market.

Our experienced engineering staff develops the most efficient and effective prototype manufacturing processes required to align product quality with your exact specifications. We focus intently on design for manufacturability and will collaborate with your design engineers to optimize cost, yield, and speed before production begins.

We develop technologically advanced capabilities to manufacture some of the most complex products in the markets we serve. Our advanced processes allow us to manufacture from an array of complex and exotic materials. With our precision multi-axis capabilities, UMC offers state-of-the-art machining principles for a leaner end result.

Find peace of mind with precision, control and consistency.

UMC provides a wide breadth of contract manufacturing services to meet complex product needs and regulatory requirements. From final cleaning, electrical chemical deburring, assembly, and product packaging, we have you covered.

Our parts cleaning department is highly regarded in the industry – with leading edge technology at the forefront of our operations. Our 130,000+ sq ft state-of-the-art manufacturing campus boasts fully automated wash lines and robotic deburring, polishing, and blasting work cells. Our polishing capabilities allow us to produce extremely fine, mirrored finishes to meet the most stringent of requirements.