Automation – Optimizing Efficiency & Saving Costs

Optimizing Success with Automation

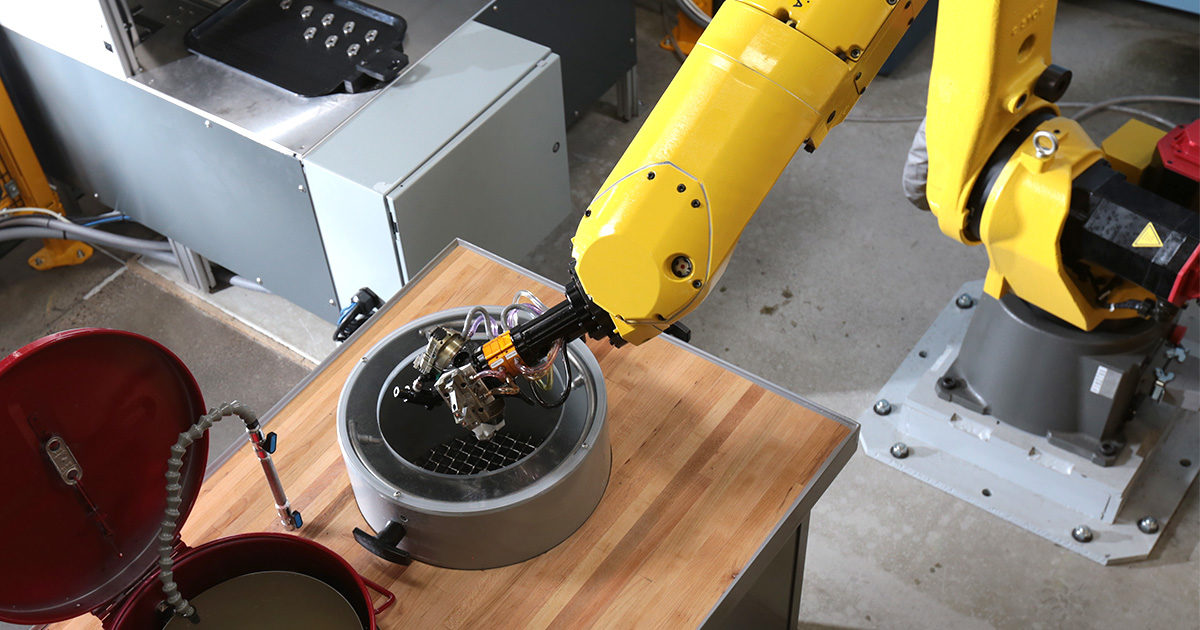

At UMC, automation is a powerful tool for efficiency and optimization. From developing less labor-intensive work flows for setup and deburring to in-machine probing and robotics, our processes are designed to maximize output and efficiency for high-complexity parts. We have a cost-effective mindset and the ingenuity to apply automation where it’s most needed.

Our team takes pride in producing high precision parts and developing solid processes for their manufacturing. Many manufacturers implement automation once a certain volume threshold is reached. At UMC, we never wait. We’re always working to get ahead of the game and develop automation strategies.

What makes UMC different is that we’re always looking at ways to automate and cut costs for our customers.

– UMC Director

High Complexity. No Problem.

No matter the complexity of any project, UMC works to develop and implement automation strategies to optimize efficiency and cut costs for all of our clients. Our team takes pride in producing high precision parts and developing solid processes for their manufacturing. We’re always working to get ahead of the game and develop automation strategies at any volume.

Continuous Improvement

Automation plays a major role in UMC’s dedication to continuous improvement. From setup to inspection, we’re always optimizing to ensure there’s no time wasted as parts move through our shop. In simplifying processes, we are able to produce complex parts in the most efficient ways possible by utilizing pallet change technology, robotics, automated inspection, bar feeding, and more. In 2018 alone, we reinvested $1,965,000 into our automation technology and processes to ensure our clients have access to the latest and greatest in manufacturing.

Better Process. Better Parts.

To engineer better parts, we take the time to engineer better processes. At UMC, we have an eye for the future and the flexibility to grow and evolve with our clients to meet their needs. Through automation, we are able to work smarter – finding new ways to innovate the production process of complex parts and deliver superior results.