UMC Open House Highlights

UMC Open House Highlights

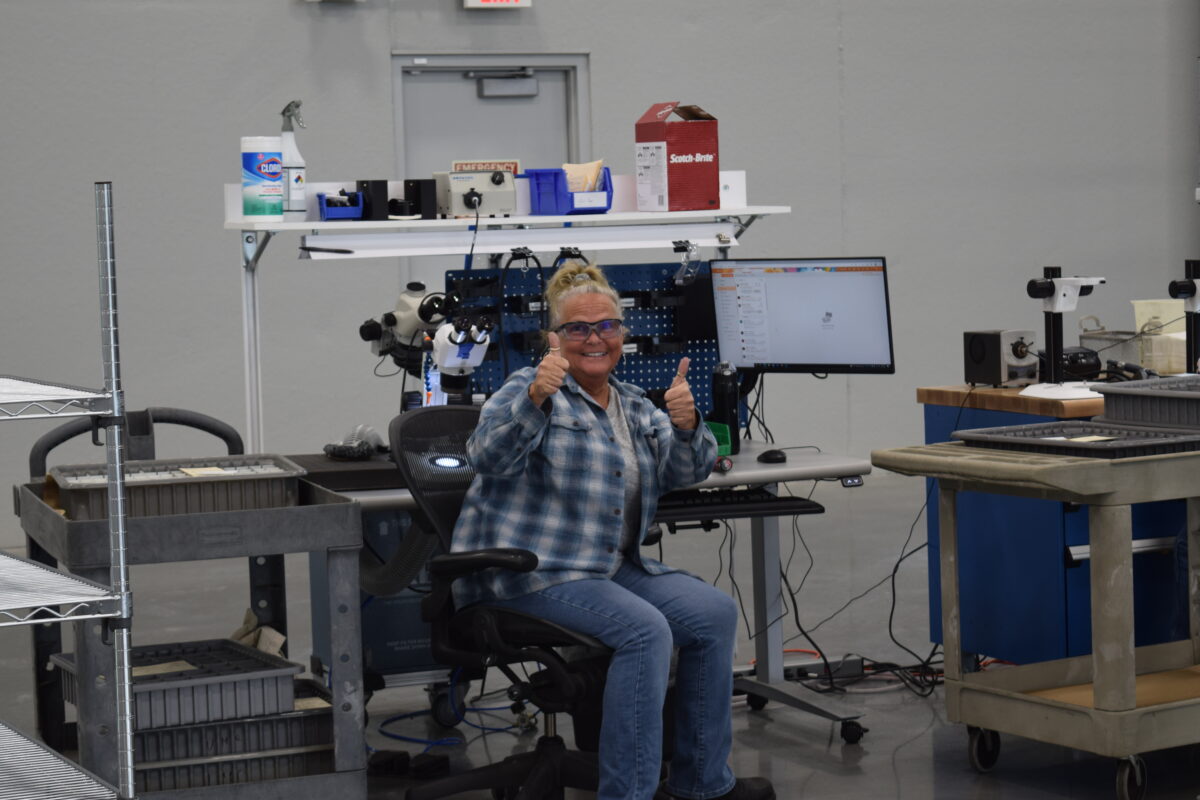

On June 22, the community gathered at Ultra Machining Company (UMC) in Monticello, MN, for the first look at UMC’s new state-of-the-art expansion project. Attendees had the opportunity to meet employees, learn about UMC, tour the facility, and experience the exciting opportunities in modern precision manufacturing. If you couldn’t join us, here are some highlights from the event.

What precision manufacturing is all about

Attendees had the opportunity to learn more about the critical work UMC does and what makes our work challenging and rewarding.

- UMC makes medical components and aviation fuel delivery parts.

- As a contract manufacturer, UMC doesn’t own any designs we produce. Still, we add value by making a completed part out of raw materials with as much precision and efficiency as possible.

- UMC specializes in parts that you can fit in the palm of your hand down to the size of the tip of a pen.

- UMC’s parts affect thousands of people’s lives annually, whether it’s somebody having an operation or flying in an aircraft.

An inspiring story of Minnesota-grown innovation

Don Tomann shared the history of UMC and its founding spirit of innovation and integrity.

- UMC is a family-owned business started in 1968 by Terry and Mary Tomann.

- Terry was a machinist by trade. In 1968, Terry founded UMC at 30 years old and with nine children at home.

- Terry’s first focus was to improve employment conditions for machinists, something not many shops were addressing at the time. He saw an opportunity to treat people better and build a stronger, more innovative business.

- UMC is rooted in the idea of “Going Beyond Others.”

- Twenty years ago, UMC built a 70,000 square ft. state-of-the-art facility in Monticello, MN. Now the company has completed an expansion that will allow it to lead in the future of precision manufacturing innovation.

Diving into Automation

Comparing the existing facility to the expansion, you can see the evolution of UMC in action.

- To keep up with growing market demand, UMC has emphasized leveraging automation to improve efficiency and drive high-quality customer results.

- At UMC, automation does not replace workers but allows them to learn and earn more throughout their careers by adding value to themselves and the business.

- Average machine usage rates are around 45%, but UMC invests in machines and automation that pull up to 80-90% of throughput time.

- Automation goes beyond robots, although UMC has several of those. Automation also encompasses probes that inspect parts in the machine, autonomous vehicles that move parts and materials throughout the facility, and automated coolant lines that can sense and respond to different conditions and fluid levels

Tapping into the Excitement for the Future

Open House attendees had the opportunity to experience the many elements of the building, people, and culture that make UMC a unique employer and a valuable community asset. As a community-focused organization, UMC will continue to invest in building and nurturing relationships with anyone interested in learning more about the exciting opportunities in the future of precision manufacturing.

Please reach out with questions or to request a tour. You can also see the list of current job openings here.

Thanks to the beloved community surrounding and supporting UMC in our mission to Go Beyond Others as Innovators Transforming Manufacturing.