Four Questions to Ask Your Manufacturing Partner Before Investing in a Precision Prototype

Outstanding products start with a well-orchestrated prototype process. A prototype is a crucial part of working through a concept from start to finish while establishing critical details, refining design, and exploring manufacturing options.

UMC’s machinists and engineers frequently create prototypes as a model for checking a part’s dimensions and tolerances before moving it to full-scale production. The prototype process is also an opportunity to collaborate and provide actionable feedback to improve the end design, manufacturability, and product lifecycle. But not all prototypes are equal. Here are some questions to ask of your manufacturing partner before investing in a precision prototype of your product.

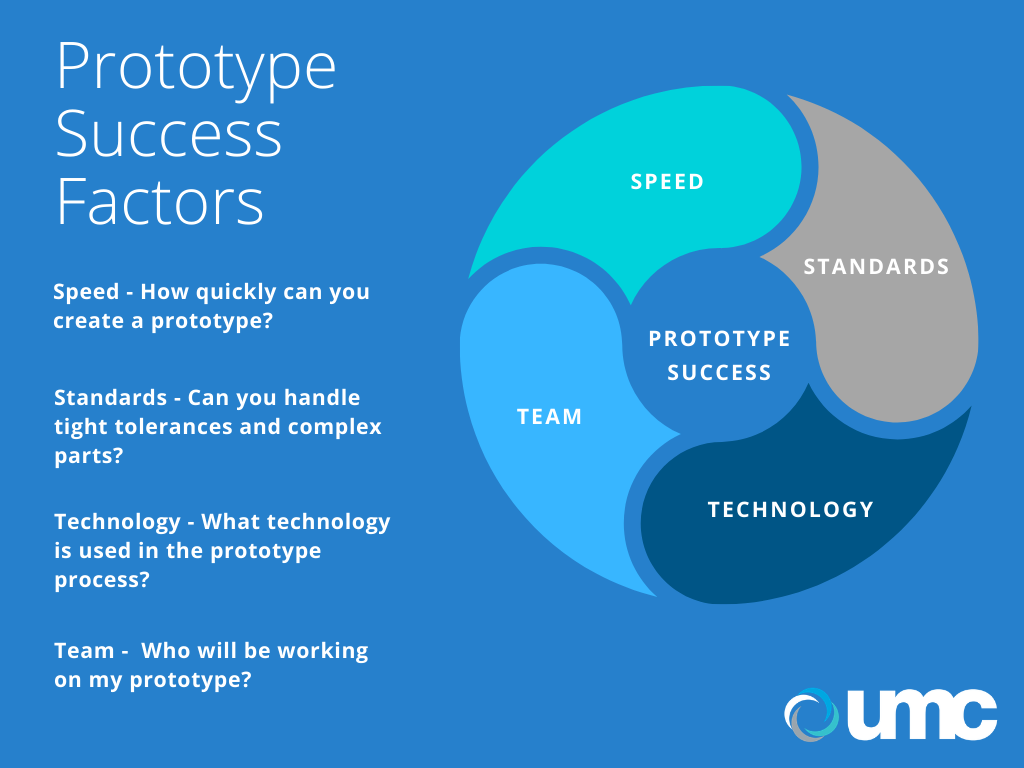

How quickly can you create a prototype?

Moving your prototype forward quickly helps you get to market faster. In-house prototyping can create a bottleneck for large corporations, causing projects to lose momentum and miss opportunities. Look for a prototyping partner that has the capacity and experience to rapidly and efficiently create your prototype.

UMC has dedicated resources allowing our team to create a prototype within just a few days. Ask your prototype partner about their turnaround times, equipment, and people you’ll have access to during the process.

Can you handle tight tolerances and complex parts?

If you’re creating a complex part that requires a great deal of accuracy, you want to know your prototype will be designed by someone with experience performing complex machining tasks to rigorous specifications. Your prototype partner should also have access to the machines and equipment needed to produce the surface finishes and tolerances you need on all of the materials you may be considering.

UMC manufactures some of the most complex products in highly regulated industries. We’ve helped design and manufacture thousands of parts and components for top companies in the medical, aerospace, and defense industries. We use advanced processes to manufacture from an array of complex and exotic materials.

Your prototype is inspected in our coordinate measuring machine (CMM), and we include a full inspection report with every prototype.

What technology is used in the prototype process?

Creating a competitive, scalable prototype requires access to the same technology used during full-scale production. UMC’s dedicated prototyping cell includes machines and technology for multi-axis, precision machining with tolerances of up to .0002”. We are committed to creating your prototype to match the manufacturing environment it will enter upon production.

Who is on the prototyping team?

The most significant advantage in the prototyping process comes from the team working on your prototype: The better the team, the more value is added to your design. It’s not just technical experience that matters—you want a team with a track record for successful collaboration and prototyping.

UMC’s prototyping team regularly helps the world’s leading OEM’s design and refine their products. With years of experience providing manufacturing feedback, our goal is to save companies as much time and money as possible while maintaining the highest quality standards.

Bonus Question: So, what do we get for all of that?

Investing in a quality prototype early on can pay big dividends later. Going through the prototyping process with the right team and technology is the best way to improve and optimize product design for a successful production launch.