Design For Manufacturability

Our experienced engineering staff is focused on supporting you from early development throughout production.

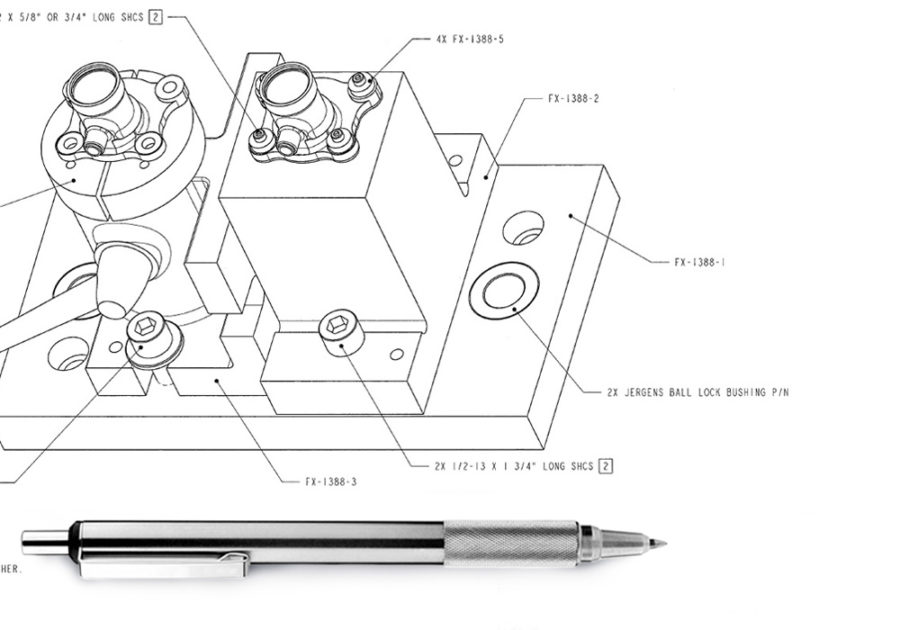

We will partner with your product development teams early on in the process – harnessing creativity and innovation to maximize efficiency and reduce overall costs in the program. Design for Manufacturability (DFM) is a valuable tool that we incorporate to ensure a successful product launch and mitigate risk for technical issues and delays.

We achieve efficiency and consistency through prototyping and creativity.

Speed is life. UMC’s prototyping services utilize dedicated resources to enable completion of small quantities, as few as one, within days. This independent department supports our customers with their qualification and testing requirements and assists you in your effort to be first to market.

Our experienced engineering staff develops the most efficient and effective prototype manufacturing processes required to align product quality with your exact specifications. We focus intently on design for manufacturability and will collaborate with your design engineers to optimize cost, yield, and speed before production begins.

Our technologically advanced capabilities allow us to manufacture some of the most complex products in the markets we serve. Our advanced processes allow us to manufacture from an array of complex and exotic materials. With our expert team and precision multi-axis capabilities, UMC offers state-of-the-art machining principles for a leaner end result.

- 1135724 Parts Produced in FY2022

- 196611 Machine Hours in FY2022

We are transforming precision manufacturing with cutting edge technologies.

At UMC, our top priority is to make sure we’re ready to help our customer’s face the current and upcoming challenges in their specific markets. We’re constantly seeking out information and making plans to be a more prepared and valuable resource. By adding new technology, integrating automation, decreasing downtime, and staying ahead of requirements and regulations, we are proactively pushing progress to set a new standard in manufacturing.

At UMC, we’re always investing in new technologies to stay on the cutting edge of our industry.

UMC Sales Engineer